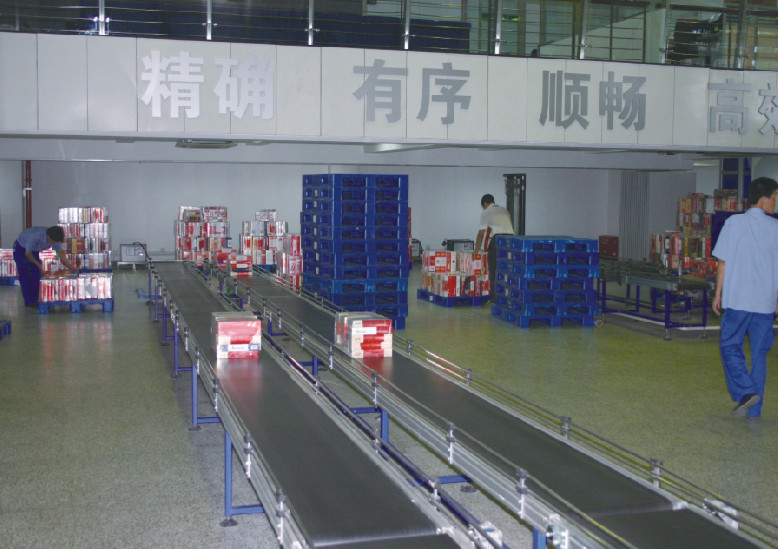

Model: LBC

This conveyor is widely applied in light industry, food, medicine and daily chemical industries.It can be equipped with working tables on both sides, optional lights, air tubes, tool hooks, operation boards, instrument desks or sockets. It usually acts as an assembly line to help factory increase efficiency and get more convenience. It also intends to:

* Increase the efficiency of material handling work* Decrease the intensity of labor, and quantity of labor

* Protect items from manual impact damages

* Save overall cost for modern enterprise management

Application:

Assembly line, small parts transfering, general material tranfering in workshops especially

Features:

Large and stable distribution, little noise, simple structure and easy to maintain, low energy consumption |

Relative Products: |

|

|

| Items | Options | ||||||||||

| Conveyor Form | Linear, Curved, Levered, L-shaped, Z-shaped, C-shaped, O-shaped, etc | ||||||||||

| Belt Type | Optional both in material, color and brand; green or black PVC & white PU most common choices | ||||||||||

| Frame Material | Painted carbon steel, Powder coated carbon steel, Stainless steel, Aluminum profile, etc | ||||||||||

| Conveyor Length | Optional, usually 3m, 5m, 6m, 10m, 20m, 30m, etc | ||||||||||

| Conveyor Width | 0ptional, 600mm effective as a factory standard | ||||||||||

| Conveyor Height | Optional, 700mm as a factory standard | ||||||||||

| Belt Thickness | Optional, 3mm as a factory standard | ||||||||||

| Side Frame Overheight | Optional, usually even or 20mm higher | ||||||||||

| Speed | Constant or variable, 10-20m/min as a factory standard | ||||||||||

| Belt Direction | Unidirectional or bidirectional | ||||||||||

| Capacity | Optional, usually 30-50kg/meter | ||||||||||

More Pictures for Reference